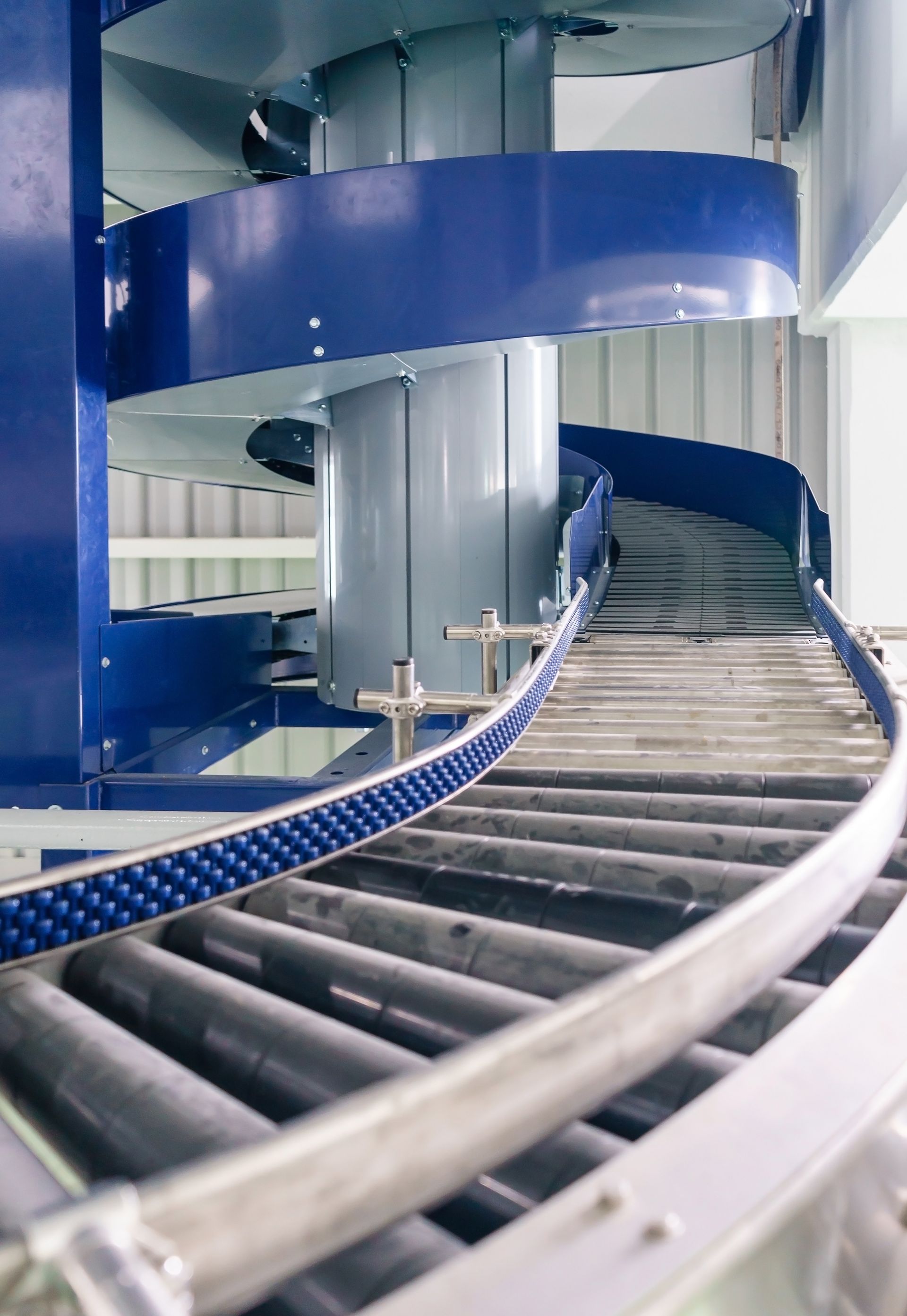

Florida’s Leading Conveyor Belt Maintenance Experts

Industrial operations depend completely on conveyor belts to keep their productivity high yet efficient. Reliable maintenance practices on conveyor systems ensure maximum investment repayment because these systems represent substantial initial costs. Keeping a conveyor belt correctly maintained prevents equipment-related accidents and breakdowns as well as premature wear that shortens its lifespan. Conveyor Tek delivers

expert conveyor belt maintenance services across Florida while providing complete

conveyor belt servicing everywhere we operate. Our service offerings include preventative maintenance alongside routine checks and belt repair as our professionals maintain the smooth functioning of your conveyor systems.

Why Conveyor Belt Maintenance is Important

Correct functioning of the conveyor belt system is essential to the success of your operations. Through proper conveyor maintenance services, equipment remains functional, loss of productivity is minimized, and unplanned failures are kept to a minimum. The following are some of the key reasons why maintenance of conveyor belts is such a serious matter.

Reduces Downtime

Unfortunately, malfunctions can halt your production line and cause delays. Through preventive belt care and periodic inspections, it is possible to microscopically detect the issues early, preventing unnecessary downtime and allowing for a continuous operation of the process.

Improves Safety

An unsafe conveyor belt can be dangerous to workers. Routine inspection and

conveyor maintenance services will also help guarantee that the system runs smoothly, reduce the risk of accidents, and keep people safe on the job.

How Conveyor Belt Maintenance Helps Your Business in Florida

Current belt maintenance standards lead to positive business results by enabling systems maximum functionality. Here’s how industrial belt maintenance can help your business:

Preventive Maintenance Saves Money

Businesses that implement preventive belt maintenance systems conduct periodic inspections perform cleaning operations, and make minimal repair work, which helps avoid major malfunction development. The proactive maintenance approach helps businesses save expenses by preventing more expensive service failures and equipment breakdowns.

Minimizes Unscheduled Downtime

Without lengthened belt observation time, small issues can turn into severe flaws that shut down complete operations. Routinely monitoring belts by inspection services lets your team spot developing issues promptly before unanticipated failures occur.

Maximizes Productivity

Your production line performs optimally when a conveyor system receives proper maintenance because it improves operational efficiency and ensures product flow throughout your business operations. The combination results in achieving full productivity and meeting all client requirements and deadlines.

Our Conveyor Belt Maintenance Services in Florida

Routine Belt Checks

Our ongoing routine belt check process helps us maintain an active inspection of your conveyor belt system's condition. We conduct screenings that examine belt degradation and other problems that might impact performance metrics within relative operating locations.

Belt Cleaning

Harbinger elements like dust and dirt and other accumulated particles on conveyor belts affect system performance alongside machinery functionality. Our belt cleaning process creates a smooth operating surface which generates less friction and increases the system's operational efficiency.

Belt Inspection Services

Routine belt inspections exist as the primary necessity to find possible issues before they develop into severe conditions. Our examination evaluates your entire system to ensure the reinstallation of crucial parts, including pulleys and rollers until the entire setup operates correctly.

Conveyor Belt Servicing

A comprehensive conveyor belt maintenance program includes tensioning, alignment, and lubrication together with wear parts replacement services at an equitable cost. The systematic approach affects both system performance and lifetime expectancy.

Conveyor Belt Repair

Our team delivers swift conveyor belt repair, enabling you to resume operation after system failures or damage occurs. The laboratory team possesses proper skills along with appropriate equipment to perform belt part and system repair work before achieving complete operability.

Preventive Belt Maintenance Plans

Through customized preventative maintenance plans we serve our clients' specific requirements. Through project proposals you implement regular planned inspection combined with cleaning maintenance and modernization to guarantee your conveyor system functions optimally at all times.

Our Process: What to Expect from Conveyor Tek

1. Initial Assessment

Our initial procedure begins with conveyor system analysis for state detection and problem identification. We use our team to review conveyor type and material transport along with frequency of use for personalized maintenance planning.

2. Scheduled Maintenance

Based on the evaluation, we build a maintenance plan, which includes periodic belt inspection services, cleaning and repair where necessary. Our group will coordinate with you to find the best time for the maintenance activities to have the least possible impact on your activities.

3. Regular Inspections

We conduct routine belt inspections to monitor the degradation of your system. This is also possible including the ability to detect problems early and to avoid unwanted failures.

4. Repairs and Adjustments

Problems are identified during the inspection, and we perform the necessary repairs or adaptations to keep your conveyor belt operational for your use. We replace worn-down components and recalibrate system tension and alignment as required.

5. Ongoing Support

There is sustained availability to us for both support and intervention, i.e., emergency repair, diagnostic, or ongoing maintenance. We are dedicated to ensuring that your conveyor system upkeep runs without problems.

Get Started Today

To ensure the long-term reliability of your conveyor system, Conveyor Tek is here to support you. Our expert team offers comprehensive industrial belt maintenance services throughout Florida and beyond.

From standard belt inspections, belt cleaning, and whatever may be necessary to repair a belt when an emergency arises, we cater to and provide whatever you ever need for your conveyor belts.

Contact us today at 863-877-7971 or email todd_bixby@conveyor-tek.com if you'd like more information about our services and how to get a maintenance program that meets your criteria.

Frequently Asked Questions

How often should I schedule conveyor belt maintenance?

We propose that a minimum examination of routine belt use should be conducted every 3-6 weeks, depending on the use frequency and types of materials being manipulated. More frequent inspections may be needed for high-volume systems.

What are the indicators that my conveyor belt is in need of servicing?

Bad things to look for in an operation that keeps a conveyor belt running smoothly are strange noises, slow speed, uneven wear, belt slippage, and visible wear on the belt. Regular belt inspections can help identify these issues early.

Can Conveyor Tek repair a damaged conveyor belt?

Yes, we provide conveyor belt repair services. Regardless if your belt is damaged as a result of wear, misalignment, or other problems, our team can repair your belt and return it to full functionality.

What does a preventive maintenance plan include?

A preventative maintenance schedule consists of inspections, cleaning, minor repairs, and adjustments to keep your conveyor belt operating at peak efficiency. It helps prevent major issues before they arise.

How long does conveyor belt maintenance take?

Maintenance time will depend on the type of service being performed. Routine examination and cleaning are normally achievable in a matter of hours, whilst more involved repairs can take several hours. We work to minimize disruption to your operations.