Florida’s Top Rack Repair Services

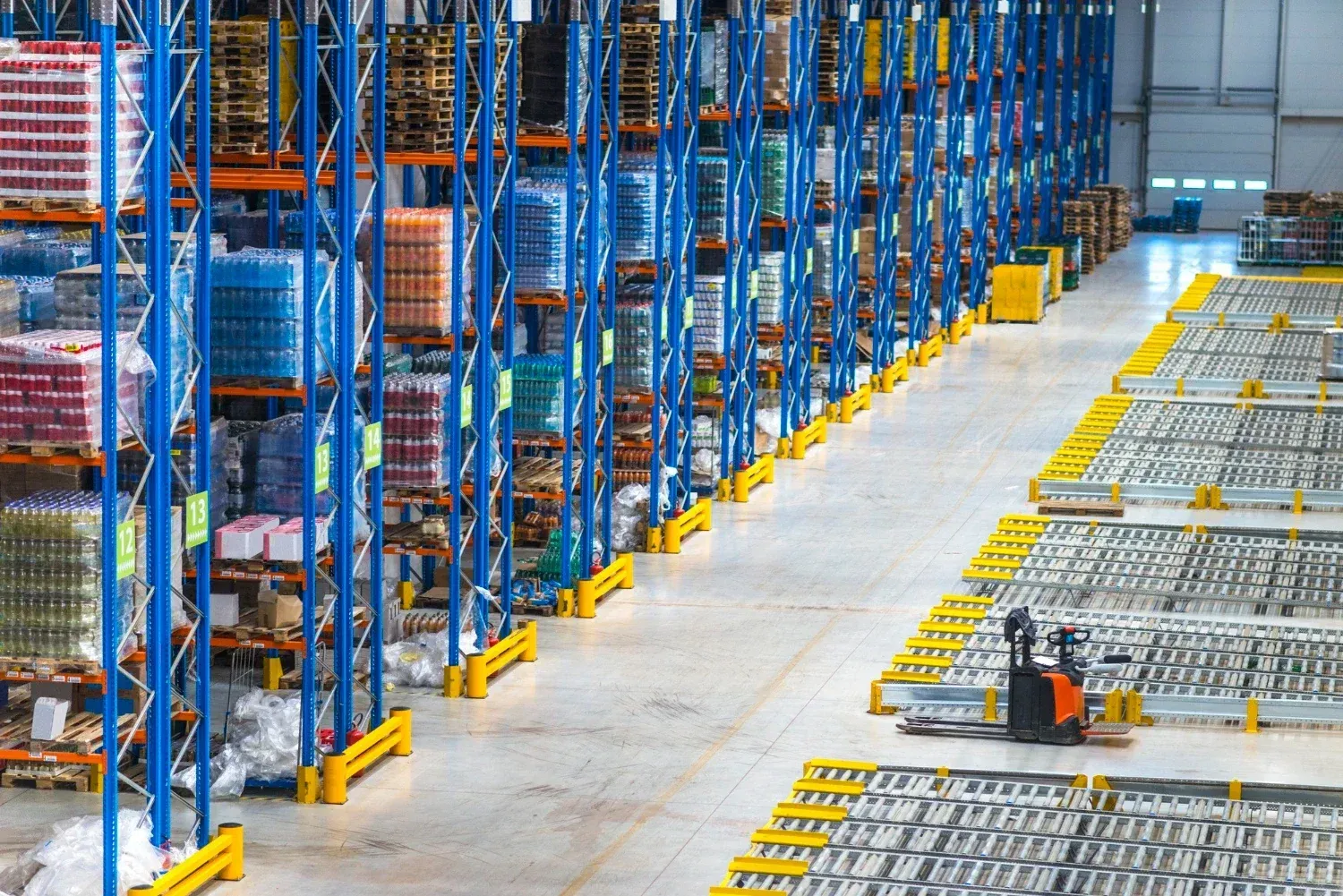

Rack occupancy is one of the factors to be considered in warehousing or a manufacturing building in order to achieve the best storage yield and operating yield. Nevertheless, due to the frequent and uncontrolled use of the racks, the racks also deteriorate or are damaged. For accidental impact by a forklift, for high loads stress or simply due to use and wear and tear, the task of rack maintenance is the most critical one to guarantee the safe and effective operation of your warehouse.

At Conveyor Tek, we are still the leaders in

industrial rack repair,

pallet rack repair, and

warehouse rack repair in the state of Florida. The work is being done by vetted personnel, no matter how big or small the rack, maintenance, refurbishment, or final structural repairs are. Our rack maintenance and rack inspection services guarantee the safety, legality, and efficiency of your racking.

Why Rack Repair Is Important for Your Business

Maintains Safety

Damaged racks are a safety hazard to your employees. Crumbling beams bowed posts, and unstable bookshelves all put the subject in a position to absorb the force from the object and to be tripped, causing further harm or pain. Day-to-day racking maintenance revolves around ensuring the maintainability of racking systems and that they remain in a safe operational condition that is safe for personnel and stock.

Prevents Further Damage

Minute error builds up over the course of time, however, that is not the case for its assessment over time. In the absence of control, even tiny cracks, bruises, or misalignment would enlarge and develop into a state of racking system breakdown. Repair of the prompt rack system postpones the appearance of minor issues that are not currently being actively addressed more major restoration jobs.

Ensures Compliance with Safety Standards

Industry facilities and warehouses in Florida must comply with Occupational Safety and Health Administration (OSHA) rules and occupational safety and health regulations to safeguard worker safety and health. The repair of degraded racks is maintained according to the following rules, which avoids liability for fines, etc.

How Rack Repair Benefits Your Business in Florida

The ability (and ultimately, the effectiveness) of the rack repair service provided depends on the availability and quality of a dependable and efficient rack repair service for your organization. Here’s how:

Cost-Effective Solution

Rack remediation is significantly less expensive than full redeployment of a rack unit. The racking systems offer specific remedies but may not always necessitate the full replacement of the system; in fact, the outputs offered by the racking system are derived by abandoning costly reworks.

Improves Warehouse Organization

Inspection services to the racks could be used to identify means of addressing issues that can be fixed to improve the blueprint and layout of the racking system, i.e., the racking itself.

Enhances Worker Productivity

Recursive optimization of employee outputs is achievable only if racks are operated in the best conditions. But, if the racks are repaired to function as they are to have sprung a leak freely, and people are not routinely finding it a major pain in the butt to get access and into or out of the material without blockers as a consequence of a defective component being fixed, etc.

Our Rack Repair Services in Florida

At Conveyor Tek, we guarantee full rack repair services in order to ensure that your racking systems remain safe and operational (and powered up) at all times. Here’s a look at the services we provide:

1. Industrial Rack Repair

The staff has long-standing experience in heavy-duty industrial rack repair and has experience with all types of heavy-duty structural heavy-duty racking employed in factories, warehouses, and distribution halls. We do repair damage, load-bearing capacity damage and misalignment and leave your racks to run at top capacity.

2. Pallet Rack Repair

Pallet racks are ubiquitous in warehousing and distribution facilities. However, if the pallet rack components are lost/damaged by a forklift or by a hefty load of pallets, our specialized personnel is there to repair the pallet racks, to make them safe and efficient again.

3. Warehouse Rack Repair

We offer repair for warehouse racks and for any rack system currently in use for storing items. No matter the degree of rack damage (crushed, overstressed, or incorrectly leveled), our team will also assess the way the damaged racks will be repaired.

4. Rack System Repair

The system repair can encompass the fault(s) of the racking system, i.e., the uprights, beams, shelf components, and the like. We then summarize the entire system in terms of both vulnerability and cure for all of its components so that your system is robust and reliable.

5. Damaged Rack Repair

No matter the impact, wear and tear, or otherwise, our team is highly experienced in damage to racking and repair. We reintroduce warped beams, faulty supports, and other damaged zones to return your racks to a walkable state.

6. Rack Maintenance

Regular rack maintenance is essential to preventing major damage. We provide ongoing support to make sure that your racks are performing as expected, which includes occasional verification and routine tuning to guarantee safe, optimal conditions of use.

7. Rack Inspection Services

We provide full rack inspection services to identify potential issues at their earliest stage. Our crew will carefully examine all of the racking to make sure it is up to code and ready to use at peak performance.

Our Process

Initial Consultation and Inspection

We begin with the problem with your frame. Our team makes a complete checkout of your racks in order to evaluate the scale of damage and determine your best option for repairs.

Customized Repair Plan

We, by inspection design, a personalized rack repair approach that is most probably suitable for your gadgets. This guideline has identified areas that must be addressed, estimated timeframes, and protective measures.

Repair and Restoration

Our group will do all the required work, from repairing damaged beams to repositioning racks. In top layer of material and technology, we are constantly making efforts to restore the full load capacity level of the racking system.

Testing and Quality Assurance

Next, we rigorously test the system upon completion of repair to make sure the system functions as it is intended. We confirm the stability, load resistance, and safety characteristics of industry standards.

Ongoing Support and Maintenance

In addition, we offer continuous support and rack support services after repair to restore system functionality after repairing. Inspection and preventive maintenance are factors that will extend the life of your racking system as well.

Get Started Today

Conveyor Tek will be provided at all times when work is required for the racking. In Florida, we provide the highest level of rack repair, which provides fast, economical, and consistent racking repair solutions to restore your warehouse racks to a safe working condition.

Call us now at 863-877-7971 or email todd_bixby@conveyor-tek.com to schedule a time to talk with us or to see what we can do to service your rack system repairs.

Frequently Asked Questions

How do I know when my racks need repairs?

Direct damage, i.e., damage to the geometry of the beams like bending, cracks, loose bolts and so on, as well as indirect damage as a misalignment, loss of stability, or implication in loading/unloading operations may indicate a need for rack repair.

Can you repair all types of racking systems?

Certainly, we are all familiar with the repair of any kind of racking structure, e.g., pallet racking, industrial shelving, or bespoke racking.

How long does a rack repair take?

The repair time depends on the type of damage. Nevertheless, repair may differ in the repaired property by at least up to a few hours, depending on the damage state, and it may take longer for larger repairs.

Do you provide maintenance services after repairs?

We offer the service of "continuous rack maintenance" (preventive maintenance to avoid the degradation of your racks to deteriorate).

What happens if I don't repair my damaged racks?

Apart from the risk of some of the safety hazards, injuries, inventory damages, and compliance breaches that may arise when attempting repairs of damaged racks, failure to repair a damaged rack may lead to economic losses. The imperative for rapidly reinstating work facilities to provide a safe and productive warehouse working environment should also be acknowledged.